Alkali-Silica Reaction Bath

HR-A0925 Alkali-Silica Reaction Bath is used to keep 25x25x285 mm concrete samples in NaOH (sodium hydroxide) at a specified temperature. The temperature can be adjusted from ambient to 100 °C using a digital thermostat with 1 °C accuracy.

Temperature can also be monitored by an external 1°C accuracy PT 100 sensor placed in the water. The bath is completely made of stainless steel and has glass cover.

Samples are placed on a special rack where each sample stays independent from each other in a vertical position. The bath is also equipped with an electronic water level indicator which gives an alarm when the water level is lower than required.

The device is used to determine the potential alkali reactivity of cement-aggregate combinations (mortar-bar method). This mould is also used for determining the length change of hardened cement paste, mortar and concrete.

By removing the special rack, Aggregate Reaction Bath can also be used as a general purpose water bath.

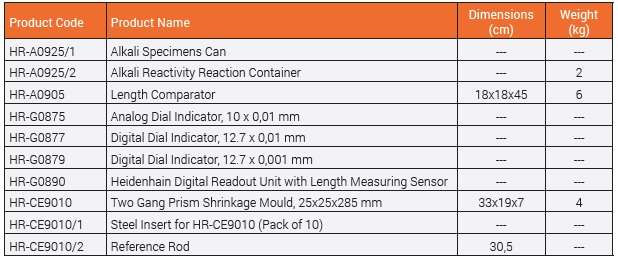

Alkali Specimens Can is manufactured from stainless steel. It has a stainless steel hanger which can hold 3 pieces 25x25x285 mm specimens.

Alkali Reactivity Reaction Container is used for the chemical determination of the potential reactivity of aggregates with alkalis in Portland cement concrete in accordance with ASTM C289, UNI 8520:22, NF P94-048 standards. It is made of stainless steel and has an airtight cover. It has a capacity of about 60 ml.

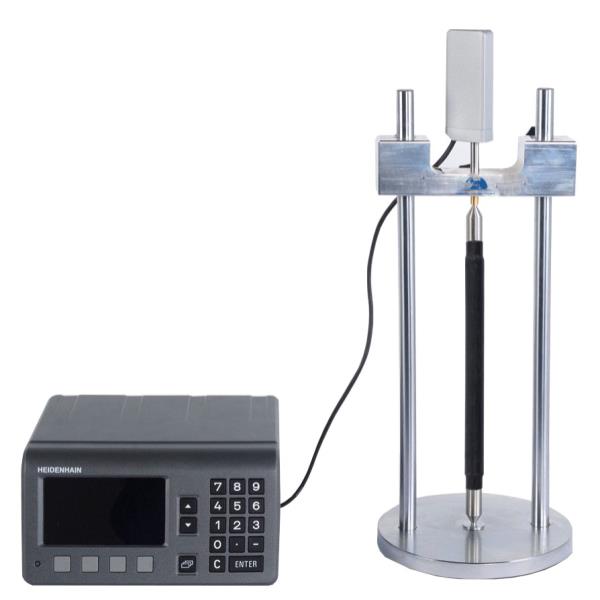

Alkali Reactivity Reaction Container, Alkali Specimens Can, Length Comparator, Analog or Digital Dial Gauge or Heidenhain Digital Readout Unit with 30x0,0001 mm Length Measuring Sensor, Two Gang Prism Shrinkage Mould, Steel Inserts and Reference Rod should be ordered separately.