Automatic Core- Rock Compression Machine (Touch Screen)

A compression test determines behavior of materials under crushing loads. The specimen is compressed and deformation at various loads is recorded.

Testing machines are supplied with EN compression platens as standard. Machines also comply with the ASTM C39 standard when used together with suitable platens.

Tests can be performed by controlling the machine either H-Touch Pro Max Control Unit or on a computer with using free HİRATEST Software which is provided free of charge with the machines. There are several advantages of performing tests on computer with using HİRATEST Software, such as reporting and graphical output.

The Automatic Core-Rock Compression Testing Machine allow inexperienced operators to perform the tests. Once the machine has been switched on and the specimen is positioned and centered by the help of centering apparatus. The only required operations are;

- Setting test parameters, including pace rate (only required when the specimen type is changed).

- Pressing the START button on the control unit

- The machine automatically starts the rapid approach, when the specimen touches the upper platen the rapid approach is ended and starts loading at the pace rate that selected by user and stops once the specimen fails.

- Automatically saves the test parameters and test results.

Load Frame,

Automatic Hydraulic Power Pack,

H-Touch Pro Max Control Unit,

Distance Pieces, Ø 165x30 mm, Ø 165x50 mm and Ø 165x80 mm,

Upper Platen (with ball seating assembly) Ø165 mm,

Lower Platen Ø165 mm,

Loading Cylinder Assembly & Limit Switch for safety,

Front and Rear Protective Doors for safety.

H-GUI Software and Ethernet Cable.

Core-Rock Compression Load Frame

Load Frame is 600 kN Capacity.

The frames are supplied with factory calibration certificate for force transfer stability and the self-alignment of the upper loading platen conforming to EN 12390-4.

The platens enable the testing of a wide variety of cylinder or similar samples.

-

Manufactured from high quality steel, which is then hardened, smoothed and finished.

-

The roughness value for the surface texture of the auxiliary platens is ≤ 3.2 µm.

-

Ø 165 mm Upper Platen (with ball seating assembly) and Lower Platen have centering rings on the lower platens for proper centering of 100 mm and 150 mm cylinder samples.

Distance pieces are used to reduce the amount of vertical clearance between the upper platen and the lower platen. Supplied with Ø 165x25 mm, Ø 165x50 mm and Ø 165x80 mm distance pieces.

Automatic Hydraulic Power Pack, dual stage, controlled by H-Touch Pro Max Control Unit is designed to supply the required oil to the load frames for loading.

Controller unit has a simple and compact configuration. The Hydraulic Power Pack, Control and Read out Units are positioned on the right-hand side of the load frame for easier accessibility, increased productivity and for safer operations.

Very silent power pack can load the specimen between 1 kN/sec. to 20 kN/sec, with an accuracy of ±5%. A Rapid approach pump is supplied as standard. Safety valve (maximum pressure valve) is used to avoid machine overloading.

Maximum working pressure of the system is 400 bar.

1. Low pressure gear pump

2. High pressure radial piston pump

High Precision Pressure Transducer

- Early age(2 or 3 days) compression strength tests

- Flexural and splitting tests by using proper accessories

- Mortar (Cement) compression tests by using proper accessories

- Core Testing

These property allows high accuracy at very low sample failures. (Class 1 at 6 kN to 600 kN)

The user can choose Load Cell or Transducer in the order stage.

All the operations of H-Touch Pro Max Control Unit are controlled from the front panel color resistive of TFT-LCD Touchscreen display and function keys.

The unit has easy to use menu options.

It displays all menu option listings simultaneously, allowing the operator to access the required option in a seamless manner to activate the option or enter a numeric value to set the test parameters.

H-Touch PRO Max Control Unit enable simultaneously display machine status, test values, warnings during operation and test graphs such as load-time or load-displacement curves in real time.

Digital graphic display of the unit is able to draw real-time "Load vs. Time" or "Stress vs. Time" graphics.

Main Features of H-Touch Pro Max Control Unit

- 2 analog channels for load cell or pressure sensors or displacement sensors.

- Can control 2 frames

- Provides load control of two separate testing frames with Closed-loop PID.

- Optionally supplied-integrated thermal printer (If requested, must be specified in the order)

- Real-time numeric display of load, loading rate and load/ time curves with automatic resolution adjustment on the touchscreen

- Up to 8-point calibration support and adjustable digital gains for every channel

- User-customizable load, position limits and test termination conditions

- Backup and recall option for device settings

- Recalling to factory default settings option.

- Easy recall of embedded test parameters for different types of tests and sample sizes

- Storage capacity up to 10.000 test result or 80 hours real time data recording with 1 sample per second recording interval (recording interval is variable).

- Graph axes on touchscreen can be configured for different tests and configurations

- The axes of the graph drawn on the device can be set to constant maximum values or axes can be automatically scaled according to the data

- Three different unit system selection; kN- Mpa -mm or lbf- psi- in or kgf- kgf/cm²- cm

- Real time and adjustable date/time.

- Multi-language support (English, French, Spanish, Turkish, Russian…)

- LAN connection for instantaneous transfer of test data to PC.

- USB port support for transfer of test data to a flash drive.

- Password Protection for machine settings, calibration and channel menus

- Record of test results in txt and MS excel format on pre-defined intervals

- 5 different visual themes

- Customizable IP

-

2 fully customizable analog channels with 24-bit ADC and PGA-FPGA circuit

-

800x480 pixel and 65535 color resolution TFT-LCD touchscreen

-

33 Hz control loop

-

32 Bit, 120 MHz ARM CORTEX M3 micro-PROcessor (CPU) for data acquisition

-

32 Bit, 400 MHz ARM CORTEX M3 micro-PROcessor (CPU) for data display

-

Additional memory support up to 32 GB via external USB flash drive

-

Support for -optionally supplied- integrated thermal printer

-

Real time display of test graph

-

LAN connection for instantaneous transfer of test data to PC.

-

USB port support for transfer of test data to a flash drive

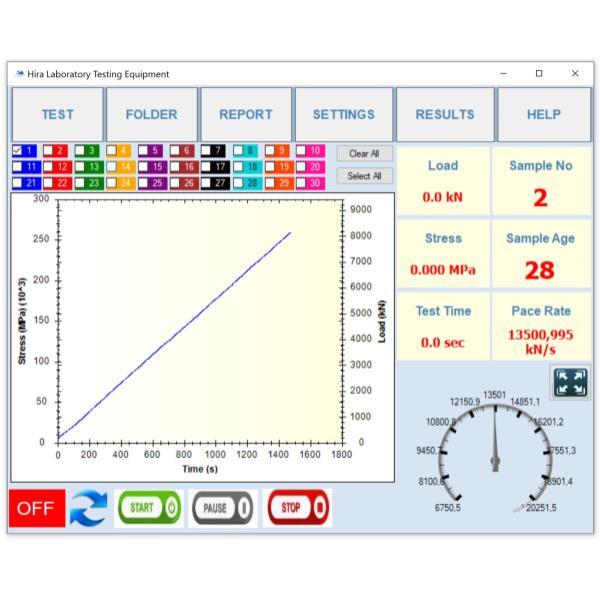

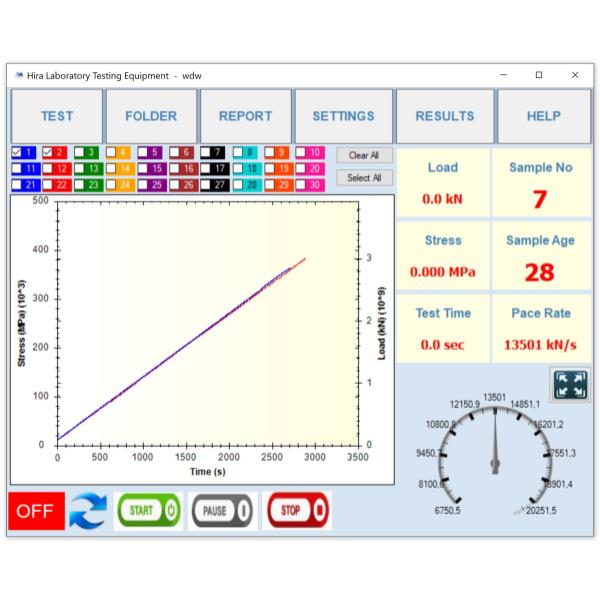

HİRATEST H-GUI Software has been designed for data acquisition, processing controlling, presentation and reporting compressive, flexural and splitting tensile strength tests of construction materials such as concrete, cement mortar, masonry units, paving blocks, roofing tiles with appropriate Automatic Compression/Flexure Testing Machines and also with a computer.

The Automatic Compression Machine can be controlled (Start, Stop commands) by a computer with the HİRATEST H-GUI Software free of charge.

The advanced functions for database management provide an easy navigation of all saved data.

Test parameters can be set and details about the test carried out such as Test Type, Sample Type, Report details, Customer details, Sample details and other information required can be entered in the software.

This informations and "Load vs. Time" or "Stress vs. Time" graphics can be seen and printed out on the Test Report.

- Compressive Strength of Concrete Cylinders / Cubes

- Flexural Strength of Concrete Beams

- Compressive Strength of Cement Mortars

- Flexural Strength of Cement Mortars

- Tensile Splitting Strength of Concrete Paving Blocks

- Tensile Splitting Strength of Concrete Cylinders / Cubes

- Flexural Strength of Roofing Tiles

- Flexural Strength of Concrete Kerbs

- Compressive Strength of Masonry Units

Main Features of H-GUI Software

- Multi-language support and customizable user interface

- 30 Tests Results, Graphics and Properties Storage Capacity in One Test File

- Exporting test results to database

- Advanced test graphical interface

- Option to store and recall test information

- Modification of test machine parameters using the software

- Able to save frequently used texts in memory and recall them when necessary

- Exporting reports and graphs

- Flexible report and graph formats

- Help and user manual display

• Pace rate control from 1 kN/sec to 20 kN/sec dependingon piston size.

• Can control 2 frames (optional)

• Can make test with load control.

• Real time display of test graph.

• Analog channels for different frame load cells

• RS-232 serial port connecting for computer interface

• LCD display

• 2 different unit system selection; kN and kgf

• Multi-language support (English and Turkish)

• 2 different unit system selection; SI and Metric

• Real-time clock and date

• Free of charge PC software for the test control and printout the test report.

Main Features of the device

- Pace rate control from 1 kN/sec to 20 kN/sec depending on piston size.

- Accuracy Class 1 acc. to EN 12390-4 starting from with the 5% of the machine capacity (Special calibration option Class 1 starting from 1% of the full range with HR-C8003)

- Supplied with factory calibration certificate for force transfer stability and the self-alignment of the upper loading platen conforming to EN 12390-4

- Tests automatically with closed loop control

- Tests can be performed by controlling the machine either H-Touch Screen Digital Readout Unit or on a computer with using free HİRATEST Software which is provided free of charge with the machines.

- Load measurement with a pressure transducer

- Hydraulic pump with dual stage for rapid approach

- Welded steel walled frame with a single acting piston

- Piston return at the end of test automatically

- Multi-Point calibration function for the channels

- Optionally supplied-integrated thermal printer (If requested, must be specified in the order)

- Ethernet port connecting for computer interface

- H-Touch Screen Digital Readout Unit

- Free of charge HİRATEST Software for the test control and printout the test report.

• Maximum pressure valves to avoid machine overloading

• Piston travel limit switch

• Emergency stop button

• Software controlled maximum load value

• Front and rear transparent durable Plexiglas guards

EN 12390-3, EN 12390-4; BS 1881, ASTM C39

-TABLO%202.jpg)

-TABLO%201.jpg)

-YEDEK%20PAR%C3%87A.jpg)