Automatic Flexural Testing Machine, Touch Screen

Machines confirm all EN, ASTM and BS standards written above. These also meet the requirements of CE norms for the safety and health of the operator.

Tests can be performed by controlling the machine either H-Touch Pro Max Control Unit or on a computer with using free HİRATEST Software which is provided free of charge with the machines. There are several advantages of performing tests on computer with using HİRATEST Software, such as reporting and graphical output.

The Automatic Flexural Testing Machines allow inexperienced operators to perform the tests. Once the machine is switched on and the specimen is placed. The only required operations are;

- Setting test parameters, including pace rate (only required when the specimen type is changed).

- Pressing the START button on the control unit

- The machine automatically starts the rapid approach, switches the test speed after 1% of the load capacity of the machine and stops once the specimen failure.

- Automatically saves the test parameters and test results.

The Automatic Flexural Testing Machines consist of;

Software and Ethernet Cable.

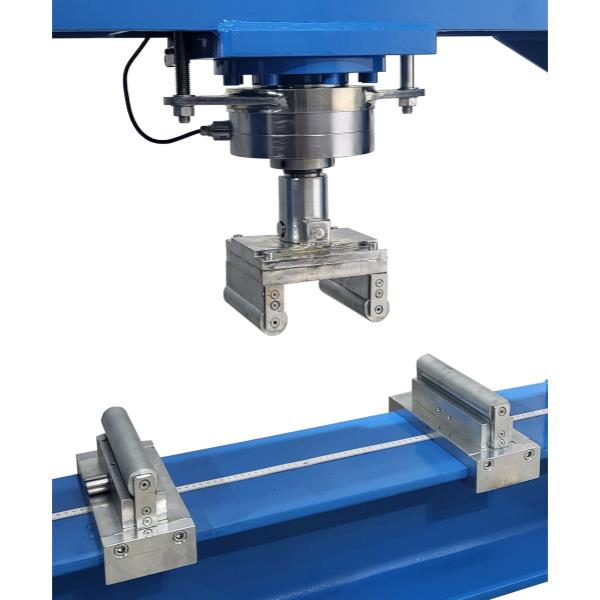

The multipurpose HİRA Flexural Testing Frames are designed for minimum deflection at maximum load resulting in very high accuracy. The load frame is a welded steel fabrication carrying the ram fitted to the steel base. All Frames have a single acting up stroking ram with over travel switch protection to stop the machine when maximum ram travel is reached. A load cell is used for load measurements on all frames.

Flexural Frames are designed to accept all accessories required for flexural or compression tests.

Flexural Frames are 100 kN, 200 kN, 300 kN capacity U Type designed to allow easy and practical front loading of the specimen.

The very rigid C type design is ideal either for conventional flexural test or for more sophisticated tests such as deformability and ductility index.

The load frame provides the stability needed for accurate and repeatable test results over the years of operation.

All frames can be connected to HİRA compression machine as a second frame or can be used with any HİRA power pack as an independent Flexural Machine.

The main characteristics are:

• High stability welded assembly

• High accuracy load measurement with load cells

• Can accept wide range of accessories for mentioned standards

• Can be connected to HİRA Compression Machine or Hydraulic Power Pack

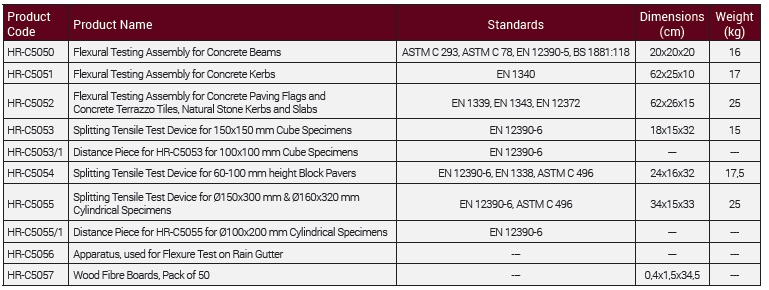

FLEXURAL TESTING ACCESSORIES

Flexural Testing Assembly for Concrete Beams

The set consist of 2upper and 2 lower rollers of Ø38 x 160 mm.

The distance of lower bearers can be adjusted between 100mm and 800mm. The distance between upper bearers can be set to 100mm or 150 mm.

For 3 point testing one of the bearers can be removed and the other placed in the center.

Flexural Testing Assembly for Concrete Kerbs

The set consists of 2 lower rollers ofØ 20x 620mm and Ø 40 mm upper loading piston with ball seating assembly.

The distance of lower rollers can be adjusted between 100 mm to 800 mm.

Flexural Test Assembly for Concrete Paving Flags and Concrete Terrazzo Tiles, Natural Stone Kerbs and Slabs

The test assembly is used for flexural tests on Concrete Paving Flags and Concrete Terrazzo Tiles, Natural Stone Kerbs and Slabs.

The set consists of 2 lower rollers and upper roller of Ø 20x 620 mm.

The distance of lower rollers can be adjusted between 100 mm to 800 mm.

Splitting Tensile Test Device for Block Pavers

Splitting Tensile Test Device for Block Pavers is accessory for compression machines for measuring the splitting tensile strengths of 60-100 mm height x 220 mm length concrete block pavers according to the requirements of the related standards.

Splitting Tensile Test Device for Concrete Cubes

Splitting Tensile Test Device for Concrete Cubes is accessory for compression machines for measuring the splitting tensile strengths of 150 mm cube concrete specimens according to the requirements of the related standards.

Distance Piece for Splitting Tensile Test Device for Concrete Cubes

Can be used for 100 mm cube concrete specimens by using this Distance pieces with Splitting Tensile Test Device for Concrete Cubes.

Splitting Tensile Test Device for Cylinders

Splitting Tensile Test Device for Cylinders is accessory for compression machines for measuring the splitting tensile strengths of Ø150x300 mm and Ø160x320 mm cylindrical specimens according to the requirements of the related standards.

Distance Piece for Splitting Tensile Test Device for Cylinders

Can be used for Ø100x200 mm Cylindrical Specimens by using this Distance pieces with Splitting Tensile Test Device for Concrete Cylinders.

HYDRAULIC POWER PACK AND AND H-TOUCH PRO MAX CONTROL UNIT

Hydraulic Power Pack

Automatic Hydraulic Power Pack, controlled by H-Touch Pro Max Control Unit is designed to supply the required oil to the load frames for loading.

Controller unit has a simple and compact configuration. The Hydraulic Power Pack is equipped with 4 wheels for easy carriage and flexible installation.

Very silent power pack can load the specimen between 1 kN/sec. to 20 kN/sec, with an accuracy of ±5%. Safety valve (maximum pressure valve) is used to avoid machine overloading.

Maximum working pressure of the system is 400 bar.

The single stage pump is formed by;

High pressure radial piston pump

On the single stage pump,high pressure radial piston pump is used for test execution.

Motor

The motor which drives the dual pumps in an AC motor and it is controlled by motor inverter. The variation in the oil flow is executed with the variation of the rotation speed of the motor.

Distribution Block

A distribution block is used to control the oil flow direction supplied by the single stage pump, the following parts are fitted to the distribution block; Solenoid valve, Safety valve (max. pressure valve), Load Cell and High pressure radial piston pump.

High Precision Pressure Transducer (Optional)

• Early age(2 or 3 days) compression strength tests

• Flexural and splitting tests by using proper accessories

• Mortar (Cement) compression tests by using proper accessories

• Core Testing

Oil Tank

The tank includes enough oil to fill the mechanism which pushes the ram during the test. The level and oil temperature can be seen on the indicator fitted to the tank. It has 25 L capacity. Hydraulic motor oil, number 46, must be used.

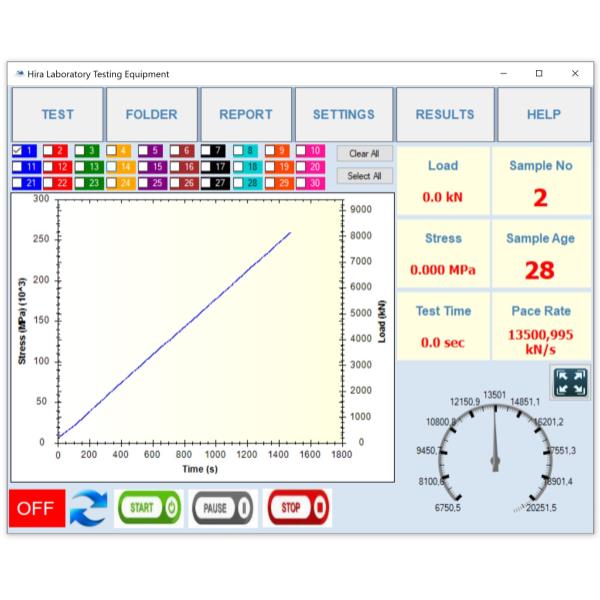

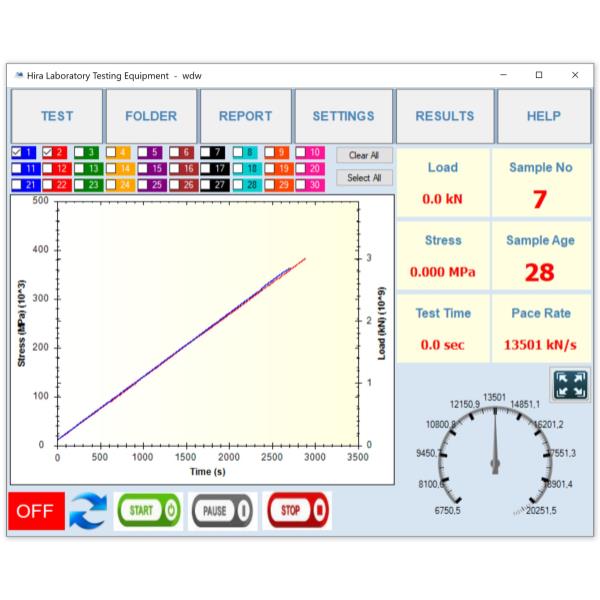

Digital Data Acquisition & Control System

HİRATEST H-Touch Pro Max Control Unit is designed to control the automatic compressive, flexural and splitting tensile strength tests of construction materials such as concrete, cement mortar, masonry units, paving blocks, roofing tiles by processing of data from load-cells, pressure transducers or displacement transducers which are fitted to the machine.

All the operations of H-Touch Pro Max Control Unit are controlled from the front panel color resistive of TFT-LCD Touchscreen display and function keys.

The unit has easy to use menu options.

It displays all menu option listings simultaneously, allowing the operator to access the required option in a seamless manner to activate the option or enter a numeric value to set the test parameters.

H-Touch PRO Max Control Unit enable simultaneously display machine status, test values, warnings during operation and test graphs such as load-time or load-displacement curves in real time.

Digital graphic display of the unit is able to draw real-time "Load vs. Time" or "Stress vs. Time" graphics.

- 2 analog channels for load cell or pressure sensors or displacement sensors.

- Can control 2 frames

- Provides load control of two separate testing frames with Closed-loop PID.

- Optionally supplied-integrated thermal printer (If requested, must be specified in the order)

- Real-time numeric display of load, loading rate and load/ time curves with automatic resolution adjustment on the touchscreen

- Up to 8-point calibration support and adjustable digital gains for every channel

- User-customizable load, position limits and test termination conditions

- Backup and recall option for device settings

- Recalling to factory default settings option.

- Easy recall of embedded test parameters for different types of tests and sample sizes

- Storage capacity up to 10.000 test result or 80 hours real time data recording with 1 sample per second recording interval (recording interval is variable).

- Graph axes on touchscreen can be configured for different tests and configurations

- The axes of the graph drawn on the device can be set to constant maximum values or axes can be automatically scaled according to the data

- Three different unit system selection; kN- Mpa -mm or lbf- psi- in or kgf- kgf/cm²- cm

- Real time and adjustable date/time.

- Multi-language support (English, French, Spanish, Turkish, Russian…)

- LAN connection for instantaneous transfer of test data to PC.

- USB port support for transfer of test data to a flash drive.

- Password Protection for machine settings, calibration and channel menus

- Record of test results in txt and MS excel format on pre-defined intervals

- Customizable IP

- 2 fully customizable analog channels with 24-bit ADC and PGA-FPGA circuit

- 800x480 pixel and 65535 color resolution TFT-LCD touchscreen

- 33 Hz control loop

- 32 Bit, 120 MHz ARM CORTEX M3 micro-PROcessor (CPU) for data acquisition

- 32 Bit, 400 MHz ARM CORTEX M3 micro-PROcessor (CPU) for data display

- Additional memory support up to 32 GB via external USB flash drive

- Support for -optionally supplied- integrated thermal printer

- Real time display of test graph

- LAN connection for instantaneous transfer of test data to PC.

- USB port support for transfer of test data to a flash drive

HİRATEST H-GUI Software has been designed for data acquisition, processing controlling, presentation and reporting compressive, flexural and splitting tensile strength tests of construction materials such as concrete, cement mortar, masonry units, paving blocks, roofing tiles with appropriate Automatic Compression/Flexure Testing Machines and also with a computer.

The Automatic Flexural Testing Machine can be controlled (Start, Stop commands) by a computer with the HİRATEST H-GUI Software free of charge.

The advanced functions for database management provide an easy navigation of all saved data.

Test parameters can be set and details about the test carried out such as Test Type, Sample Type, Report details, Customer details, Sample details and other information required can be entered in the software.

This informations and "Load vs. Time" or "Stress vs. Time" graphics can be seen and printed out on the Test Report.

Following tests can be done with the HİRATEST H-GUI Software;

- Compressive Strength of Concrete Cylinders / Cubes

- Flexural Strength of Concrete Beams

- Compressive Strength of Cement Mortars

- Flexural Strength of Cement Mortars

- Tensile Splitting Strength of Concrete Paving Blocks

- Tensile Splitting Strength of Concrete Cylinders / Cubes

- Flexural Strength of Roofing Tiles

- Flexural Strength of Concrete Kerbs

- Compressive Strength of Masonry Units

- Multi-language support and customizable user interface

- 30 Tests Results, Graphics and Properties Storage Capacity in One Test File

- Exporting test results to database

- Advanced test graphical interface

- Option to store and recall test information

- Modification of test machine parameters using the software

- Able to save frequently used texts in memory and recall them when necessary

- Exporting reports and graphs

- Flexible report and graph formats

- Help and user manual display

- Pace rate control from 1 kN/sec to 20 kN/sec depending on piston size.

- Tests automatically with closed loop control

- Tests can be performed by controlling the machine either H-Touch Screen Digital Readout Unit or on a computer with using free HİRATEST Software which is provided free of charge with the machines.

- Load measurement with a load cell

- Multi-Point calibration function for the channels

- Optionally supplied-integrated thermal printer (If requested, must be specified in the order)

- Ethernet port connecting for computer interface

- H-Touch Screen Digital Readout Unit

- Free of charge HİRATEST Software for the test control and printout the test report.

- Maximum pressure valves to avoid machine overloading

- Piston travel limit switch

- Emergency stop button

- Software controlled maximum load value

EN 1338, 1340, 12390-5, 12390-6, BS 1881, ASTM C78, C293, C496

_pdf%20TABLO%203.JPG)

-tablo.JPG)

_pdf%20TABLO%202.JPG)