Digital Marshall Stability Test Machine

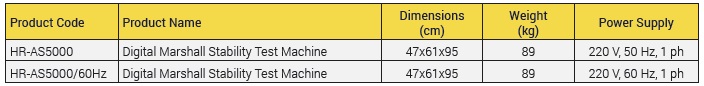

The HR-AS5000 50 kN Capacity Digital Marshall Stability Test Machine is used to determine the maximum load and flow values of bituminous mixtures.

The machine comprises of a robust and compact two column frame with adjustable upper cross beam. The unit is a bench mounting compression frame with motor and worm gear housed within the base unit. It is designed to operate with the minimum of maintenance.

Platen rate is 50.8 mm/min also maintained under load thanks to an overpowered electric motor.

For safety, the up and down travel of the lower platen is limited the use of limit switches. Rapid adjustment of the platen is controlled using the up and down buttons on the digital readout unit.

The measuring system consists of a 50 kN capacity Load cell fitted to the upper cross beam to read stability values and the 25 mm Displacement Sensor fitted to the Breaking Head.

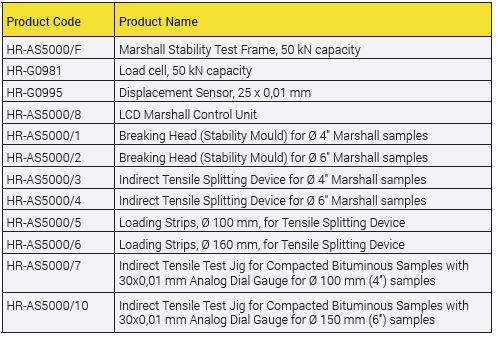

Supplied complete with LCD Marshall Control Unit, 50 kN capacity Load Cell, 25 x 0.01 mm Linear potentiometric displacement transducer with holder, Breaking Head (Stability Mould) for Ø 4" Marshall samples.

Breaking Head (Stability Mould) for Ø 6" Marshall samples, Indirect Tensile Splitting Device for Ø 4" Marshall samples, Indirect Tensile Splitting Device for Ø 6" Marshall samples, Loading Strips, Ø 100 mm, for Tensile Splitting Device, Loading Strips, Ø 160 mm, for Tensile Splitting Device and Indirect Tensile Test Jig for Compacted Bituminous Samples with 30x0,01 mm Analog Dial Gauge for Ø 100 mm (4”) & Ø 150 mm (6”) samples should be ordered separately.

The machine comprises of a robust and compact two column frame with adjustable upper cross beam. The unit is a bench mounting compression frame with motor and worm gear housed within the base unit. It is designed to operate with the minimum of maintenance.

Platen rate is 50.8 mm/min also maintained under load thanks to an overpowered electric motor.

For safety, the up and down travel of the lower platen is limited the use of limit switches. Rapid adjustment of the platen is controlled using the up and down buttons on the digital readout unit.

The measuring system consists of a 50 kN capacity Load cell fitted to the upper cross beam to read stability values and the 25 mm Displacement Sensor fitted to the Breaking Head.

Supplied complete with LCD Marshall Control Unit, 50 kN capacity Load Cell, 25 x 0.01 mm Linear potentiometric displacement transducer with holder, Breaking Head (Stability Mould) for Ø 4" Marshall samples.

Breaking Head (Stability Mould) for Ø 6" Marshall samples, Indirect Tensile Splitting Device for Ø 4" Marshall samples, Indirect Tensile Splitting Device for Ø 6" Marshall samples, Loading Strips, Ø 100 mm, for Tensile Splitting Device, Loading Strips, Ø 160 mm, for Tensile Splitting Device and Indirect Tensile Test Jig for Compacted Bituminous Samples with 30x0,01 mm Analog Dial Gauge for Ø 100 mm (4”) & Ø 150 mm (6”) samples should be ordered separately.

EN 12697-34, 12697-23, 12697-12, 13108, ASTM D1559, AASHTO T245, AASHTO T283