Digital Marshall Stability Test Machine (Touch Screen)

The HR-AS5000/TS 50 kN Capacity Digital Marshall Stability Test Machine is used to determine the maximum load and flow values of bituminous mixtures.

The machine comprises of a robust and compact two column frame with adjustable upper cross beam. The unit is a bench mounting compression frame with motor and worm gear housed within the base unit. It is designed to operate with the minimum of maintenance.

Platen rate is 50.8 mm/min also maintained under load thanks to an overpowered electric motor.

For safety, the up and down travel of the lower platen is limited the use of limit switches. Rapid adjustment of the platen is controlled using the up and down buttons on the digital readout unit.

The measuring system consists of a 50 kN capacity Load cell fitted to the upper cross beam to read stability values and the 25 mm Displacement Sensor fitted to the Breaking Head.

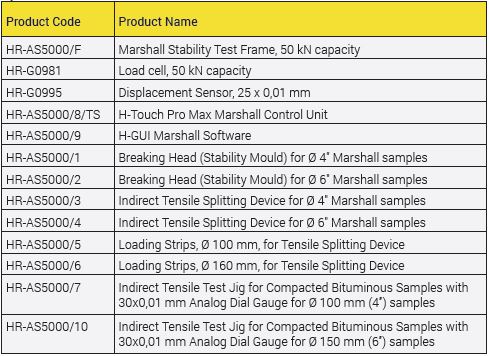

Supplied complete with HİRATEST H-Touch Pro Max Marshall Control Unit, 50 kN capacity Load Cell, 25 x 0.01 mm Linear potentiometric displacement transducer with holder, Breaking Head (Stability Mould) for Ø 4" Marshall samples, HİRATEST H-GUI Marshall Software and LAN Connection Cable.

Breaking Head (Stability Mould) for Ø 6" Marshall samples, Indirect Tensile Splitting Device for Ø 4" Marshall samples, Indirect Tensile Splitting Device for Ø 6" Marshall samples, Loading Strips, Ø 100 mm, for Tensile Splitting Device, Loading Strips, Ø 160 mm, for Tensile Splitting Device and Indirect Tensile Test Jig for Compacted Bituminous Samples with 30x0,01 mm Analog Dial Gauge for Ø 100 mm (4”) & Ø 150 mm (6”) samples should be ordered separately.

H-TOUCH PRO MAX MARSHALL CONTROL UNIT

HİRATEST H-Touch Pro Max Marshall Control Unit is designed to control Marshall Test Machine to perform by processing of data from displacement transducers which are fitted to the machine.

All the operations of H-Touch Pro Max Marshall Control Unit are controlled from the front panel color resistive of TFT-LCD Touchscreen display and function keys.

The Unit can perform Marshall tests as a stand-alone without the use of a PC or with the HİRATEST H-GUI Marshall Software and a PC. Control of machine, acquisition of load and displacement data in real time are provided by the unit.

The unit has easy to use menu options.

It displays all menu option listings simultaneously, allowing the operator to access the required option in a seamless manner to activate the option or enter a numeric value to set the test parameters and see all the data while the test running.

Main Features of H-Touch Pro Max Marshall Control Unit

- Flow and stability values are automatically calculated and saved,

- Ability to perform displacement-controlled tests,

- Real time display of test graph

- 2 analog channels for load cell and displacement sensors

- Multi-language support (English, French, Spanish, Turkish)

- Real-time date/time

- Test results display and memory management interface

- Calibration function for channels

- Programmable digital gain adjustment for load-cell and potentiometric sensors, voltage and current transmitters

- Closed loop PID for steady pace rate

- Connection and control feature via Ethernet

- Free computer software for test control and enhanced report output

Hardware

- Permanent storage capacity up to 10 0000 test results

- 1/256000 dot resolution for each channel

- 10 data acquisition per second (at sample rate) on each channel

- 2 fully customizable analog channels with 24-bit ADC and PGA-FPGA circuit

- Ethernet port for computer connection

- 800x480 pixel and 65535 color resolution TFT-LCD touchscreen

- 33 Hz control loop

- 32 Bit, 120 MHz ARM CORTEX M3 micro-PROcessor (CPU) for data acquisition

- 32 Bit, 400 MHz ARM CORTEX M3 micro-PROcessor (CPU) for data display

- Choice of three unit systems: kN, ton or lb

- Additional memory support up to 32 GB via external USB flash drive

- Support for -optionally supplied- integrated thermal printer

- LAN connection for instantaneous transfer of test data to PC.

- USB port support for transfer of test data to a flash drive

Software

HİRATEST H-GUI Marshall Software has been designed for Marshall stability tests in accordance with EN 12697-34, ASTM D 1559, D5581, D 6927, AASHTO T 245, NF P98-0251-2 indirect tensile tests in accordance with EN 12697-23 EN 12697-12 (method A), ASTM 6931, AASHTO T283.

The software includes control of machine, acquisition of load and displacement data, generating and saving reports.

Test type is selected in the software and then the sample height is entered as the test parameter. It automatically calculates correction factor coming from the standards with respect to specimen thickness. The stability value is calculated regarding this factor.

The software continuously updates load and displacement until the end of test. When the test is completed, the sharpest slope of the graph is calculated. The sharpest slope is shifted 1.5 mm to the right side of the graph and the intersection between 2nd slope and original test data is recorded as the stability value for the test. The horizontal distance between the intersection of first slope and X axis and intersection of test data with 2nd slope is recorded as “flow” value.

The report includes all results for 4 samples. The user can see 4 of the results on the same screen for easy comparison.

Main Features of H-GUI Marshall Software

- Multi-language support and user interface

- Refreshing Experiment Graphic Displays on the Screen in Real Time

- Able to save frequently used texts in memory and recall them when necessary

- Modification of test machine parameters using the software

EN 12697-34, 12697-23, 12697-12, 13108, ASTM D1559, AASHTO T245, AASHTO T283

_pdf-TABLO.jpg)