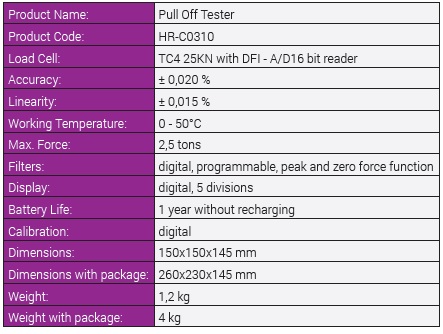

Pull Off Tester (Drc)

The LDV Pull-Off Tester provides a quick and easy way to determine the adhesion force between two different surfaces/materials. The Pull-Off tester is generally used to check the adhesion of different kind of materials (i.e. plastic, synthetic, fabric and others), fixed to concrete surfaces.

The Pull-Off test can be run on site without the need for installing or preparing any equipment during the casting process or while the part is being made.

The test consists in gluing a metal plate to the part being tested: the plate is then pulled off the part, using a top support complete with extraction system coupled to a load cell.

The pull off force is shown on the instrument’s digital display. The peak value is logged.

Thanks to its versatile attachment system, the LDV Pull-Off tester can be used for testing the adhesion of mechanical components (anchors) and components which are larger than conventional plates, using support extenders.

The extended point of support makes it possible to test elements which are larger than normal adhesion plates.

Shear tests apply a traction force to a strip of composite material along its length, thus distributing tangential stresses across the interface between the reinforcement and the substrate as specified by ASTM D 905.

As indicated in the CNR document, the test is particularly valuable in determining the quality of adhesion.

The application can be considered acceptable if at least 80% of the tests (both, if only two are run) register a peak force at failure of no less than 24 kN.

The Pull-Off tester for shear testing composite structures includes a position-adjustable lower contrast plate and the anchor plates for the material being tested (LDV-S).

The instrument consists of a lower support which is bolted to the substrate to which the material being tested by the SHT Pull-Off tester is affixed.

Fields of Application

- Any application in which the adhesion between two different materials is to be measured;

- Checking restoration work on damaged concrete structures;

- Work using carbon fibre.

The instrument can be used with bitumen, cement, mortar, plaster, plastics and fabrics.

Reading system with DaTa 500 connection

The result is displayed either by the removable external force reader, which facilitates display when the test position is difficult to access, or by connecting the pull-off tester to the DaTa 500 reader with the cable included in the kit.

Pull Off LDV is supplied complete with Contrast Support, Loading Cell (25 o 50 kN) and Removable Display System, Adjustable Ball Traction Handles, Support Extensions, Pull-off Plate D50, Calibration Report, User Manual and Rigid Carry Case.

Pull Off LDV-T is supplied complete with Contrast Support, Loading Cell (25 o 50 kN) and Removable Display System, Adjustable Ball Traction Handles, Support Extensions, Pull-off Plate D50, Calibration Report, User Manual, Rigid Carry Case, Lower Contrast Plate and (L 200 x 50)Shear Test Plate.

Support Shear Test LDV-S is supplied complete withLower Contrast Plate and (L 200 x 50)Shear Test Plate.

The Pull-Off test can be run on site without the need for installing or preparing any equipment during the casting process or while the part is being made.

The test consists in gluing a metal plate to the part being tested: the plate is then pulled off the part, using a top support complete with extraction system coupled to a load cell.

The pull off force is shown on the instrument’s digital display. The peak value is logged.

Thanks to its versatile attachment system, the LDV Pull-Off tester can be used for testing the adhesion of mechanical components (anchors) and components which are larger than conventional plates, using support extenders.

The extended point of support makes it possible to test elements which are larger than normal adhesion plates.

Shear tests apply a traction force to a strip of composite material along its length, thus distributing tangential stresses across the interface between the reinforcement and the substrate as specified by ASTM D 905.

As indicated in the CNR document, the test is particularly valuable in determining the quality of adhesion.

The application can be considered acceptable if at least 80% of the tests (both, if only two are run) register a peak force at failure of no less than 24 kN.

The Pull-Off tester for shear testing composite structures includes a position-adjustable lower contrast plate and the anchor plates for the material being tested (LDV-S).

The instrument consists of a lower support which is bolted to the substrate to which the material being tested by the SHT Pull-Off tester is affixed.

Fields of Application

- Any application in which the adhesion between two different materials is to be measured;

- Checking restoration work on damaged concrete structures;

- Work using carbon fibre.

The instrument can be used with bitumen, cement, mortar, plaster, plastics and fabrics.

Reading system with DaTa 500 connection

The result is displayed either by the removable external force reader, which facilitates display when the test position is difficult to access, or by connecting the pull-off tester to the DaTa 500 reader with the cable included in the kit.

Pull Off LDV is supplied complete with Contrast Support, Loading Cell (25 o 50 kN) and Removable Display System, Adjustable Ball Traction Handles, Support Extensions, Pull-off Plate D50, Calibration Report, User Manual and Rigid Carry Case.

Pull Off LDV-T is supplied complete with Contrast Support, Loading Cell (25 o 50 kN) and Removable Display System, Adjustable Ball Traction Handles, Support Extensions, Pull-off Plate D50, Calibration Report, User Manual, Rigid Carry Case, Lower Contrast Plate and (L 200 x 50)Shear Test Plate.

Support Shear Test LDV-S is supplied complete withLower Contrast Plate and (L 200 x 50)Shear Test Plate.

EN 1015-12, EN 1348, ASTM C1583, ASTM D4541, BS 1881 Part 207, DIN 1048 Part 2