Semi-Automatic Concrete Compression Testing Machine

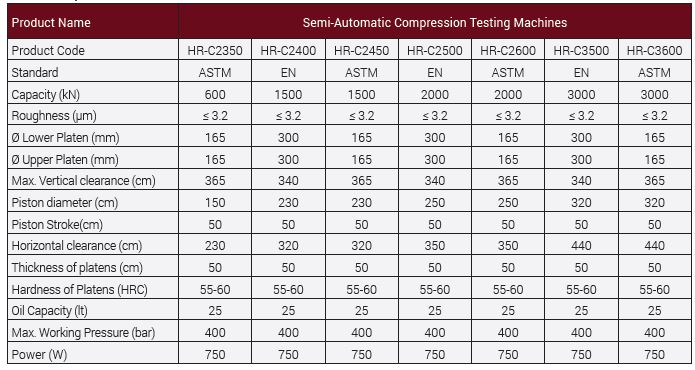

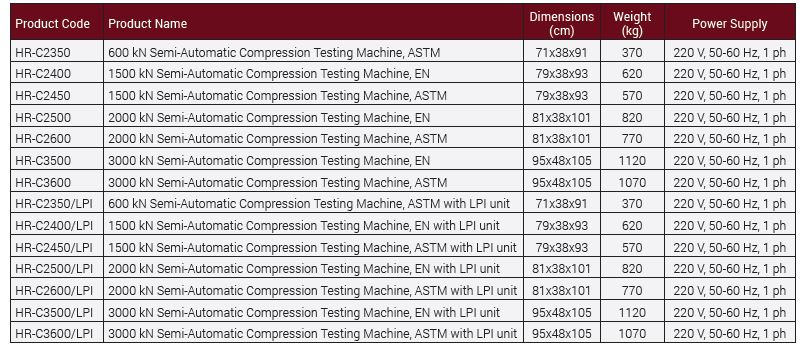

The HİRA Semi-Automatic (Motorized) range of 600 kN, 1500 kN, 2000 kN and 3000 kN capacity compression testing machines have been designed for reliable and consistent testing of a wide range of specimens. Machines confirms all EN, ASTM and BS standards written above. These also meet the requirements of CE norms for the safety and health of the operator.

The Semi-Automatic Concrete Compression Testing Machines consist of;

Load Frame,

Semi-Automatic Hydraulic Power Pack,

Digital Readout Unit or LPI Digital Readout Unit,

Distance Pieces, 30 mm, 50 mm and 80 mm,

Upper Platen (with ball seating assembly),

Lower Platen,

Loading Cylinder Assembly & Limit Switch for safety,

Front and Rear Protective Doors for safety.

Concrete Compression Load Frame

Capacities of 600 kN, 1500 kN, 2000 kN and 3000 kN Load Frames are most popular and available models for welded type frames.

The load frame provides the stability needed for accurate and repeatable test results over the years of operation. The machine's hydraulic power pack, control and read out units are positioned on the right hand side of the load frame for easier accessibility, increased productivity and for safer operations.

Upper Platens/Lower Platens

The platens enable the testing of a wide variety of cylinder, cube blocks or similar samples.

• Manufactured from high quality steel, which is then hardened, smoothed and finished.

• The roughness value for the surface texture of the auxiliary platens is ≤ 3.2 µm.

• Ø 165 mm and Ø 300 mm Upper Platen (with ball seating assembly) and Lower Platen have centering rings on the lower platens for proper centering of 100 mm and 150 mm cube, 100 mm and 150 mm cylinder samples.

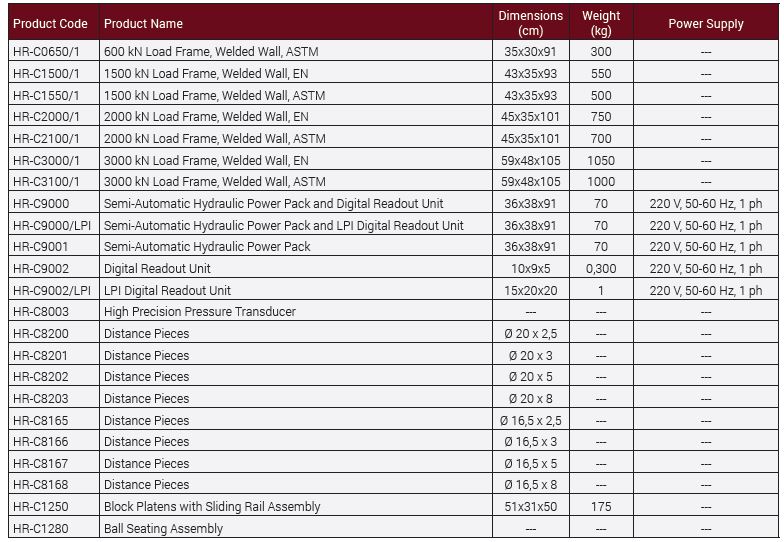

Block Platens with Sliding Rail Assembly

STANDARDS: EN 772-1, 12390-4

Block Platens with Sliding Rail Assembly are installed on the compression testing machines for testing concrete blocks and other structural materials. The Sliding Rail Assembly allows the platens to be easily installed without removing the existing Ø 300 mm compression platens. This assembly should be factory installed.

It should be noted that after installing, the vertical clearance between the platens decreases by 50 mm.

Block Platens Lifting Assembly is used for easy removal of the lower platen of Block Platens and easy replacement of the distance pieces between the piston and the lower platen.

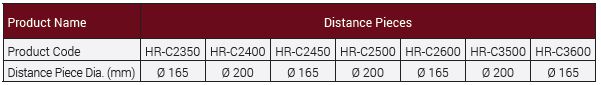

Distance Pieces

Distance pieces are used to reduce the amount of vertical clearance between the upper platen and the lower platen.

Loading Cylinder Assembly & Limit Switch

All frames have a single acting up stroking ram. The diameter of piston changes with regard to the capacity.

The maximum ram stroke is 50 mm, a limit switch is fitted to prevent over travel of the ram which cuts the power to the pump for safety.

At the end of the test process to start a new test the piston returns to default position.

The pressure transducer is used for load measurements.

There is a low friction coaxial PTFE seal between the cylinder and the piston fitted to the cylinder.

SEMI-AUTOMATIC (MOTORIZED) HYDRAULIC POWER PACK AND DIGITAL READOUT UNIT

Semi-Automatic (Motorized) Hydraulic Power Pack

The Semi-Automatic (Motorized) Power Pack, controlled by a pressure rate control valve is designed to supply the required oil to the load frames for loading. The power pack can load different frames with required pace rates. A pump is supplied as standard. The power pack is equipped with a safety valve (maximum pressure valve) to avoid machine overloading. Maximum working pressure of the system is 400 bar.

Dual Stage Pump

The dual stage pump is formed by two groups;

- Low pressure gear pump

- High pressure radial piston pump

On the dual stage pump, a high delivery, low pressure gear pump is used for rapid approach, while a low delivery, high pressure radial piston pump is used for test execution. The rapid approach facility shortens the time interval from piston start until the upper platen touches to the specimen. This excellent feature helps to save a lot of time when a large number of specimens are going to be tested.

Motor

The motor which drives the pump in an AC motor.

Distribution Block

A distribution block is used to control the oil flow direction supplied by the pump. Loading and unloading process and pace rate adjustment is done from the arms on the distribution block. The following parts are fitted to the distribution block; Safety valve (max. pressure valve) and Transducer.

High Precision Pressure Transducer

The HİRA range of Semi-Automatic Machines can be upgraded with option High Precision Pressure Transducer special calibration Class 1 starting from 1% of the full range.

This unique performance enables the machines to be used for a considerable number of applications including:

• Early age(2 or 3 days) compression strength tests

• Flexural and splitting tests by using proper accessories

• Mortar (Cement) compression tests by using proper accessories

• Core Testing

Oil Tank

The tank includes enough oil to fill the mechanism which pushes the ram during the test. The level and oil temperature can be seen on the indicator fitted to the tank. It has 15 L capacity. Hydraulic motor oil, number 46, must be used.

Digital Readout Unit

The Digital Readout Unit has been designed to use with load cells or pressure transducers on different material test applications.

The peak value and the load change during the test are displayed on the screen.

• Peak value hold property

• Easy preload zeroing

• 5 Digits

• Multi-point Calibration

LPI Digital Readout Unit

LPI Digital Readout Unit is used for reading of the applied load on load cells or pressure transducers in different material test applications.

- Can operate with 2 x AA batteries or 5V AC adapter

- Real time numeric display of load and load pressure

- 1 channel with two different calibration table (by changing the sensor belong to other frame, the unit can be control for second test frame)

- Peak hold property

- Multi-point calibration

- Easy preload zeroing

- 8 keys keyboard

- RS232 Serial port for PC or thermal or dot matrix printer

Safety Features

• Maximum pressure valves to avoid machine overloading

• Piston travel limit switch

• Emergency stop button

• Front and rear transparent durable Plexiglas guards

ASTM C39, ISO EN 7500, 12390-4

.jpg)