Semi-Automatic Flexural Testing Machine

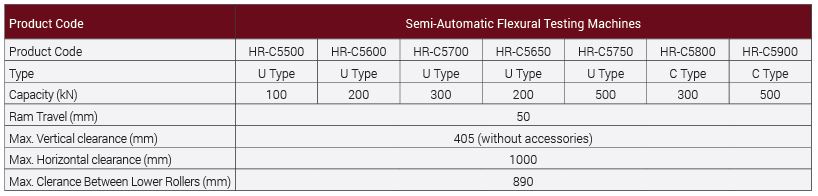

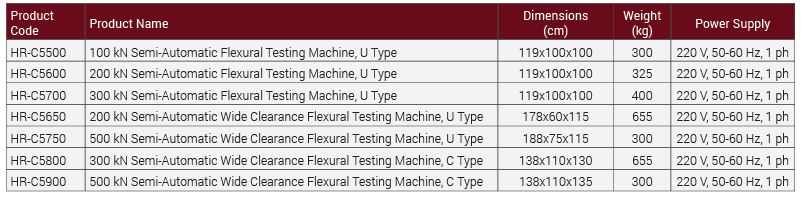

The HİRA Semi-Automatic (Motorized) range of 100 kN, 200 kN, 300 kN and 500 kN capacity Flexural Testing Machines have been designed for reliable and consistent testing of flexural test on standard concrete beams, concrete or natural stone kerbs, concrete paving flags, and natural stone slabs and tensile splitting test of concrete paving blocks with suitable apparatus.

The Semi-Automatic Flexural Testing Machines consist of;

Heavy Duty Welded Load Frame,

Semi-Automatic Hydraulic Power Pack,

Digital Readout Unit

Flexural test assemblies should be ordered separately.

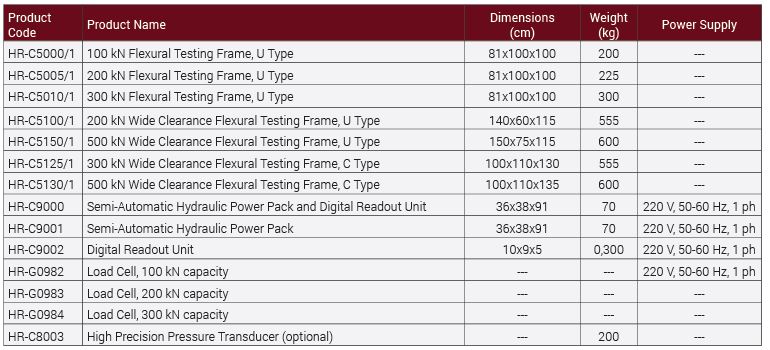

Flexural Load Frame

The multipurpose HİRA Flexural Testing Frames are designed for minimum deflection at maximum load resulting in very high accuracy. The load frame is a welded steel fabrication carrying the ram fitted to the steel base. All Frames have a single acting up stroking ram with over travel switch protection to stop the machine when maximum ram travel is reached. A load cell is used for load measurements on all frames.

Flexural Frames are designed to accept all accessories required for flexural or compression tests.

Flexural Frames are 100 kN, 200 kN, 300 kN capacity U Type, 200 kN, 500 kN capacity Wide Clearance U Type and 300 kN, 500 kN capacity Wide Clearance C Type open structure designed to allow easy and practical front loading of the specimen.

The very rigid C type design is ideal either for conventional flexural test or for more sophisticated tests such as deformability and ductility index.

The load frame provides the stability needed for accurate and repeatable test results over the years of operation.

All frames can be connected to HİRA compression machine as a second frame or can be used with any HİRA power pack as an independent Flexural Machine.

The main characteristics are:

• High stability welded assembly

• High accuracy load measurement with load cells

• Can accept wide range of accessories for mentioned standards

• Can be connected to HİRA Compression Machine or Hydraulic Power Pack

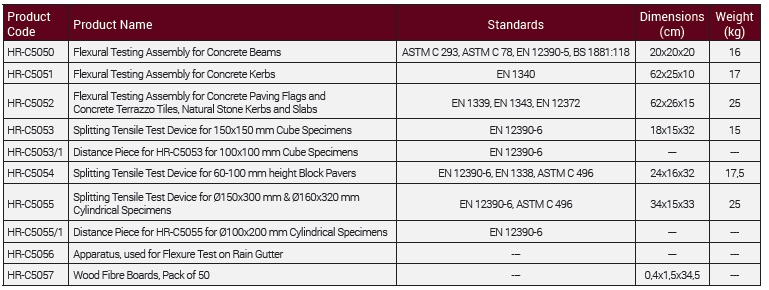

Flexural Testing Accessories

Flexural Testing Assembly for Concrete Beams

The test assembly is used for 3 or 4 point flexural tests on 100 or 150 mm Concrete Beams.

The set consist of 2 upper and 2 lower rollers of Ø38 x 160 mm.

The distance of lower bearers can be adjusted between 100mm and 800mm. The distance between upper bearers can be set to 100 mm or 150 mm.

For 3 point testing one of the bearers can be removed and the other placed in the center.

Flexural Testing Assembly for Concrete Kerbs

The test assembly is used for flexural tests on Concrete Kerbs.

The set consists of 2 lower rollers of Ø 20 x 620mm and Ø 40 mm upper loading piston with ball seating assembly.

The distance of lower rollers can be adjusted between 100 mm to 800 mm.

Flexural Test Assembly for Concrete Paving Flags and Concrete Terrazzo Tiles, Natural Stone Kerbs and Slabs

The test assembly is used for flexural tests on Concrete Paving Flags and Concrete Terrazzo Tiles, Natural Stone Kerbs and Slabs.

The set consists of 2 lower rollers and upper roller of Ø 20x 620 mm.

The distance of lower rollers can be adjusted between 100 mm to 800 mm.

Splitting Tensile Test Device for Block Pavers

Splitting Tensile Test Device for Block Pavers is accessory for compression machines for measuring the splitting tensile strengths of 60-100 mm height x 220 mm length concrete block pavers according to the requirements of the related standards.

Splitting Tensile Test Device for Concrete Cubes

Splitting Tensile Test Device for Concrete Cubes is accessory for compression machines for measuring the splitting tensile strengths of 150 mm cube concrete specimens according to the requirements of the related standards.

Distance Piece for Splitting Tensile Test Device for Concrete Cubes

Can be used for 100 mm cube concrete specimens by using this Distance pieces with Splitting Tensile Test Device for Concrete Cubes.

Splitting Tensile Test Device for Cylinders

Splitting Tensile Test Device for Cylinders is accessory for compression machines for measuring the splitting tensile strengths of Ø150x300 mm and Ø160x320 mm cylindrical specimens according to the requirements of the related standards.

Distance Piece for Splitting Tensile Test Device for Cylinders

Can be used for Ø100x200 mm Cylindrical Specimens by using this Distance pieces with Splitting Tensile Test Device for Concrete Cylinders.

SEMI-AUTOMATIC (MOTORIZED) HYDRAULIC POWER PACK AND DIGITAL READOUT UNIT

Semi-Automatic (Motorized) Hydraulic Power Pack

The Semi-Automatic (Motorized) Power Pack, controlled by a pressure rate control valve is designed to supply the required oil to the load frames for loading. The power pack can load different frames with required pace rates. A pump is supplied as standard. The power pack is equipped with a safety valve (maximum pressure valve) to avoid machine overloading. Maximum working pressure of the system is 400bar.

Single Stage Pump

The single stage pump is formed by;

High pressure pump

On the single stage pump, high pressure pump is used for test execution.

Motor

The motor which drives the pump in an AC motor.

The Semi-Automatic Flexural Testing Machines consist of;

Heavy Duty Welded Load Frame,

Semi-Automatic Hydraulic Power Pack,

Digital Readout Unit

Flexural test assemblies should be ordered separately.

Flexural Load Frame

The multipurpose HİRA Flexural Testing Frames are designed for minimum deflection at maximum load resulting in very high accuracy. The load frame is a welded steel fabrication carrying the ram fitted to the steel base. All Frames have a single acting up stroking ram with over travel switch protection to stop the machine when maximum ram travel is reached. A load cell is used for load measurements on all frames.

Flexural Frames are designed to accept all accessories required for flexural or compression tests.

Flexural Frames are 100 kN, 200 kN, 300 kN capacity U Type, 200 kN, 500 kN capacity Wide Clearance U Type and 300 kN, 500 kN capacity Wide Clearance C Type open structure designed to allow easy and practical front loading of the specimen.

The very rigid C type design is ideal either for conventional flexural test or for more sophisticated tests such as deformability and ductility index.

The load frame provides the stability needed for accurate and repeatable test results over the years of operation.

All frames can be connected to HİRA compression machine as a second frame or can be used with any HİRA power pack as an independent Flexural Machine.

The main characteristics are:

• High stability welded assembly

• High accuracy load measurement with load cells

• Can accept wide range of accessories for mentioned standards

• Can be connected to HİRA Compression Machine or Hydraulic Power Pack

Flexural Testing Accessories

Flexural Testing Assembly for Concrete Beams

The test assembly is used for 3 or 4 point flexural tests on 100 or 150 mm Concrete Beams.

The set consist of 2 upper and 2 lower rollers of Ø38 x 160 mm.

The distance of lower bearers can be adjusted between 100mm and 800mm. The distance between upper bearers can be set to 100 mm or 150 mm.

For 3 point testing one of the bearers can be removed and the other placed in the center.

Flexural Testing Assembly for Concrete Kerbs

The test assembly is used for flexural tests on Concrete Kerbs.

The set consists of 2 lower rollers of Ø 20 x 620mm and Ø 40 mm upper loading piston with ball seating assembly.

The distance of lower rollers can be adjusted between 100 mm to 800 mm.

Flexural Test Assembly for Concrete Paving Flags and Concrete Terrazzo Tiles, Natural Stone Kerbs and Slabs

The test assembly is used for flexural tests on Concrete Paving Flags and Concrete Terrazzo Tiles, Natural Stone Kerbs and Slabs.

The set consists of 2 lower rollers and upper roller of Ø 20x 620 mm.

The distance of lower rollers can be adjusted between 100 mm to 800 mm.

Splitting Tensile Test Device for Block Pavers

Splitting Tensile Test Device for Block Pavers is accessory for compression machines for measuring the splitting tensile strengths of 60-100 mm height x 220 mm length concrete block pavers according to the requirements of the related standards.

Splitting Tensile Test Device for Concrete Cubes

Splitting Tensile Test Device for Concrete Cubes is accessory for compression machines for measuring the splitting tensile strengths of 150 mm cube concrete specimens according to the requirements of the related standards.

Distance Piece for Splitting Tensile Test Device for Concrete Cubes

Can be used for 100 mm cube concrete specimens by using this Distance pieces with Splitting Tensile Test Device for Concrete Cubes.

Splitting Tensile Test Device for Cylinders

Splitting Tensile Test Device for Cylinders is accessory for compression machines for measuring the splitting tensile strengths of Ø150x300 mm and Ø160x320 mm cylindrical specimens according to the requirements of the related standards.

Distance Piece for Splitting Tensile Test Device for Cylinders

Can be used for Ø100x200 mm Cylindrical Specimens by using this Distance pieces with Splitting Tensile Test Device for Concrete Cylinders.

SEMI-AUTOMATIC (MOTORIZED) HYDRAULIC POWER PACK AND DIGITAL READOUT UNIT

Semi-Automatic (Motorized) Hydraulic Power Pack

The Semi-Automatic (Motorized) Power Pack, controlled by a pressure rate control valve is designed to supply the required oil to the load frames for loading. The power pack can load different frames with required pace rates. A pump is supplied as standard. The power pack is equipped with a safety valve (maximum pressure valve) to avoid machine overloading. Maximum working pressure of the system is 400bar.

Single Stage Pump

The single stage pump is formed by;

High pressure pump

On the single stage pump, high pressure pump is used for test execution.

Motor

The motor which drives the pump in an AC motor.

Distribution Block

A distribution block is used to control the oil flow direction supplied by single stage pump. Loading and unloading process and pace rate adjustment is done from the arms on the distribution block. The following parts are fitted to the distribution block; Solenoid valve, Safety valve (max. pressure valve), Load Cell and High pressure radial piston pump.

High Precision Pressure Transducer

The HİRA range of Semi-Automatic Machines can be upgraded with option High Precision Pressure Transducer special calibration Class 1 starting from 1% of the full range.

This unique performance enables the machines to be used for a considerable number of applications including:

• Early age(2 or 3 days) compression strength tests

• Flexural and splitting tests by using proper accessories

• Mortar (Cement) compression tests by using proper accessories

• Core Testing

Oil Tank

The tank includes enough oil to fill the mechanism which pushes the ram during the test. The level and oil temperature can be seen on the indicator fitted to the tank. It has 15 L capacity. Hydraulic motor oil, number 46, must be used.

Digital Readout Unit

The Digital Readout Unit has been designed to use with load cells or pressure transducers on different material test applications.

The peak value and the load change during the test are displayed on the screen.

• Peak value hold property

• Easypreloadzeroing

• 600 KHz High SpeedInputFrequency

• 6 Digits

Safety Features

• Maximum pressure valves to avoid machine overloading

• Piston travel limit switch

• Emergency stop button

EN 1338, 1339, 1340, 12390-5, 12390-6, BS 1881, ASTM C78, C293, C496